- Understanding Direct-to-Film Printing (DTF) Technology: A Revolutionary Approach

- Advantages of DTF Printing for Custom Designs

- Applications: Where DTF Printing Shines in Personalized Products

- The Creative Process: From Concept to Realization with DTF

- Material Considerations and Durability in DTF Printing

- Future Prospects and Trends in Personalized DTF Designs

Understanding Direct-to-Film Printing (DTF) Technology: A Revolutionary Approach

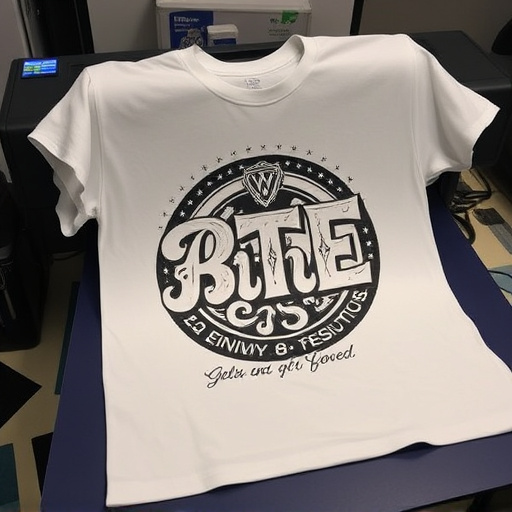

Direct-to-Film (DTF) printing technology has revolutionized personalized design and production, offering a versatile and efficient solution for various industries. This cutting-edge method eliminates the need for traditional printing processes by applying designs directly onto film, enabling seamless integration with subsequent steps in manufacturing or packaging.

DTF Printing leverages advanced machinery and inks to achieve high-quality results, ensuring vibrant colors and precise details. Its versatility allows for customized designs on a wide range of materials, from plastic and glass to metal and fabric. This technology streamlines production by reducing setup times and minimizing waste, making it an attractive option for businesses seeking efficient, cost-effective solutions without compromising quality or customization.

Advantages of DTF Printing for Custom Designs

Direct-to-film (DTF) printing offers a game-changing approach to creating personalized designs, especially for custom applications. One of its key advantages is the ability to produce high-quality prints directly on various materials, eliminating the need for intermediate steps. This technology streamlines the production process, making it an efficient choice for businesses and designers seeking quick turnaround times.

Additionally, DTF Printing allows for exceptional versatility in terms of design complexity and material options. Whether it’s a vibrant poster, a unique custom phone case, or a intricate fabric pattern, DTF can handle detailed prints with precision. This makes it ideal for industries like fashion, marketing, and entertainment, where one-of-a-kind, personalized products are in high demand.

Applications: Where DTF Printing Shines in Personalized Products

Direct-to-film (DTF) printing has found its niche in personalized product design, offering a range of applications where its unique capabilities truly shine. From custom packaging and labels to tailored marketing collateral, DTF Printing enables businesses to create eye-catching, high-quality designs with exceptional speed and flexibility. The technology’s direct application onto various film materials ensures precision and vibrant colors, making it ideal for short-run, personalized items that demand a touch of individuality.

In the realm of product branding, DTF Printing allows for custom branding on a variety of surfaces, from plastic bottles to metal cans, offering a level of personalization previously unattainable with traditional printing methods. This is particularly advantageous for small businesses and startups looking to establish their unique brand identity in a competitive market. Moreover, DTF Printing’s ability to produce complex designs with fine details makes it suitable for creating exclusive, limited-edition products, catering to the desires of discerning consumers who appreciate one-of-a-kind items.

The Creative Process: From Concept to Realization with DTF

The creative process behind personalized designs using direct-to-film (DTF) printing technology is a captivating journey from concept to realization. It all begins with an idea, be it a unique graphic, a custom logo, or an artistic illustration. Designers take this initial vision and transform it into a digital file, meticulously preparing the artwork for printing. This involves ensuring optimal image quality, color accuracy, and precision, as DTF printing demands high-resolution files to achieve exceptional results.

Once the design is ready, the magic happens. The DTF printer lays down layers of ink directly onto the film, precisely replicating the digital art. This technology offers unparalleled flexibility, allowing for intricate details, vibrant colors, and even limited-edition runs. Artists and designers can experiment with various substrates, from vinyl to fabric, bringing their concepts to life in a way that traditional printing methods struggle to match.

Material Considerations and Durability in DTF Printing

Future Prospects and Trends in Personalized DTF Designs

The future of personalized designs looks bright with direct-to-film (DTF) printing technology continuing to evolve and gain traction. As consumer demand for unique, tailored items increases, DTF Printing offers an efficient and cost-effective solution for creating one-of-a-kind products across various industries, from fashion and accessories to signage and packaging. Trends suggest a move towards even more intricate and detailed designs, with advancements in ink technology allowing for enhanced color accuracy and finer line work.

Personalization at scale is another area where DTF Printing is expected to make significant strides. With the ability to quickly adapt designs for different audiences or markets, businesses can offer highly customized products without breaking the bank. This technology also opens doors for creative collaborations, enabling artists and designers to experiment with new visual aesthetics and push boundaries in product customization.