Direct-to-film (DTF) printing is a cutting-edge technology offering precise, flexible custom design creation. It directly prints images onto film, ensuring vibrant colors and crisp outlines for various applications like clothing, accessories, and signage. DTF's versatility enables the reproduction of intricate designs with exceptional detail on multiple materials. The process involves specialized software, UV exposure, and quality control to achieve high-quality, durable transfers. DTF printing is revolutionizing sectors from fashion to marketing by offering swift, tailored product customization with endless creative potential. Future innovations aim to further enhance color accuracy, durability, and design flexibility for various surfaces.

“Discover the world of personalized design with Direct-to-Film (DTF) printing technology. This revolutionary approach allows for unparalleled customisation, transforming various industries with its versatility and quality. From understanding the core principles of DTF printing to exploring its creative applications, this article delves into the process, advantages, and future trends. Uncover the endless possibilities of DTF transfers, ensuring durability and exceptional results. Get ready to revolutionize your design game with this cutting-edge technology.”

- Understanding Direct-to-Film (DTF) Printing Technology: A Revolutionary Approach to Custom Designs

- The Advantages of DTF Transfers: Unlocking Endless Creative Possibilities

- Choosing the Right Materials for DTF Prints: Ensuring Quality and Durability

- Step-by-Step Process: From Design to Final DTF Print

- Applications of Personalized DTF Designs: Transforming Industries

- Future Trends in DTF Printing: Pushing the Boundaries of Customization

Understanding Direct-to-Film (DTF) Printing Technology: A Revolutionary Approach to Custom Designs

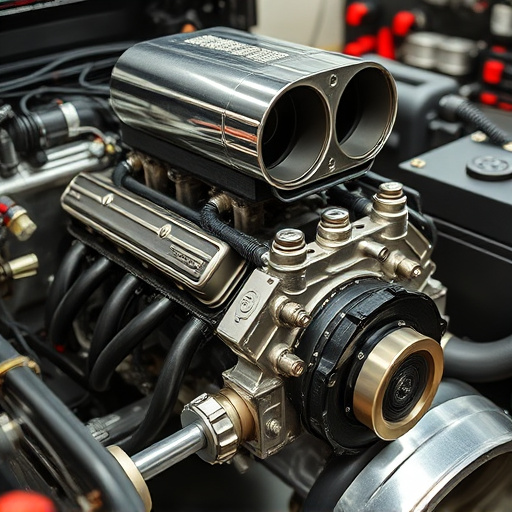

Direct-to-film (DTF) printing is a cutting-edge technology that has revolutionized the way we approach personalized designs. Unlike traditional printing methods, DTF transfers images and graphics directly onto film, offering unparalleled precision and flexibility in creating custom prints. This innovative process involves specialized equipment that applies ink to the film in exacting detail, ensuring vibrant colors and crisp outlines.

DTF printing is particularly advantageous for a wide range of applications, from clothing and accessories to promotional items and signage. Its ability to produce high-quality, durable DTF transfers makes it an ideal choice for businesses seeking unique marketing materials or individuals wanting to add personalized touches to their everyday items. With DTF Printing, the possibilities are endless, allowing for truly one-of-a-kind designs that capture the essence of individual style and brand identity.

The Advantages of DTF Transfers: Unlocking Endless Creative Possibilities

Direct-to-film (DTF) transfers offer a revolutionary approach to printing and design, unlocking an unparalleled array of creative opportunities for artists, designers, and businesses alike. One of the key advantages is its versatility; DTF technology enables the reproduction of intricate designs with exceptional detail and vibrancy on various materials, from t-shirts and mugs to posters and even stickers. This makes it an ideal choice for those seeking unique, personalized items that stand out in a sea of generic merchandise.

Moreover, DTF printing streamlines the production process by eliminating the need for costly set-up fees and complex machinery typically associated with traditional printing methods. It allows for on-demand printing, enabling small businesses and entrepreneurs to easily customize products according to customer preferences without breaking the bank. This level of customization and efficiency is especially appealing in today’s fast-paced market where trends come and go, ensuring that designs remain fresh and relevant.

Choosing the Right Materials for DTF Prints: Ensuring Quality and Durability

When it comes to choosing materials for DTF (Direct-to-Film) prints, quality and durability are paramount. The right substrate, or base material, is essential to ensure the final design looks vibrant and lasts over time. For instance, high-quality vinyl offers excellent color reproducibility and resistance to fading, making it ideal for outdoor applications or items intended for prolonged exposure. Conversely, flexible film is better suited for curved surfaces or products that require flexibility, while sturdy paper stock can be used for posters, stickers, and short-term displays where durability isn’t a primary concern.

Consideration should also be given to the DTF transfer process itself. Using compatible inks and printers designed specifically for DTF technology ensures optimal results. The right ink types, whether solvent-based or UV-curable, play a crucial role in achieving sharp details, vibrant colors, and long-lasting adhesion to the chosen substrate. Additionally, pre-treating materials properly, such as cleaning them thoroughly before printing, prevents ink from failing prematurely and ensures consistent, high-quality DTF prints every time.

Step-by-Step Process: From Design to Final DTF Print

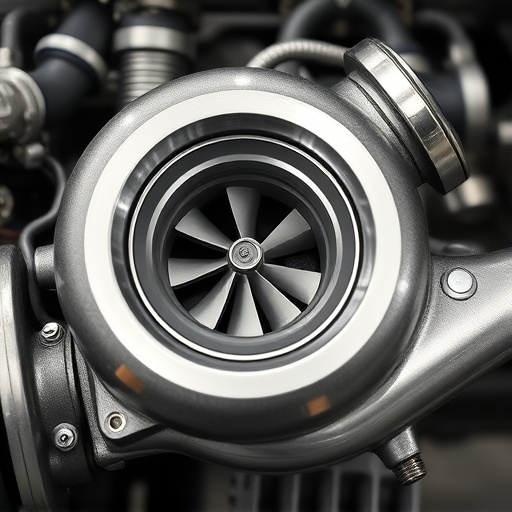

The journey from design to a final DTF (Direct-to-Film) print involves a meticulous process, ensuring each step is crucial in achieving a vibrant and precise result. It begins with artists crafting their vision onto digital canvas, using specialized software to create or edit graphics, texts, and images tailored for DTF transfer. Once the design is finalized, it’s time to prepare the film; this entails transferring the design onto transparent film sheets, ensuring every detail is crisp and clear.

The printed film is then carefully aligned and applied to the desired surface, often a t-shirt or other fabric. A crucial step is the exposure process, where a UV light source plays a vital role in setting the ink, creating a durable DTF transfer. After exposure, the excess film is precisely peeled away, leaving behind the design, now permanently infused into the fabric. The final step involves quality control, ensuring the DTF prints meet the desired standards of color accuracy and overall aesthetics.

Applications of Personalized DTF Designs: Transforming Industries

Personalized designs with direct-to-film (DTF) printing technology are revolutionizing various industries, offering endless creative possibilities. From fashion and apparel to marketing and advertising, DTF transfers have become a game-changer in creating unique, high-quality prints directly onto different materials. This innovative process allows for precise customization, enabling businesses to offer tailored products that cater to individual preferences.

In the fashion sector, DTF printing enables designers to bring one-of-a-kind garments to life, with custom patterns and graphics seamlessly integrated into clothing pieces. It’s not just limited to textiles; DTF technology also finds application in signage, allowing businesses to create eye-catching promotional materials and branded merchandise. Moreover, the versatility of DTF extends to packaging, where personalized prints enhance product presentation and brand recognition. With its ability to produce detailed DTF transfers swiftly, this technology is transforming industries by delivering exceptional, customized results.

Future Trends in DTF Printing: Pushing the Boundaries of Customization

The future of DTF printing promises exciting innovations that will further revolutionize the customization game. One prominent trend is the exploration of new materials, allowing for a broader range of applications and products. For instance, researchers are investigating ways to apply DTF technology to textiles, offering unparalleled design flexibility on clothing and accessories. This shift could lead to unique, personalized fashion statements tailored to individual tastes.

Additionally, advancements in ink formulation and printing techniques aim to enhance color accuracy and durability. With higher-resolution prints and improved ink adhesion, DTF transfers can deliver crisp, vibrant DTG prints on various surfaces. These developments suggest that DTF Printing will continue to be a game-changer in the customization industry, providing businesses and individuals with even more reasons to embrace this versatile technology for their creative projects.