Custom DTF Transfers have transformed fabric customization, offering high-quality printing on light materials at low costs. Automation in DTF printing enhances efficiency, reduces manual labor, and speeds up production times, allowing businesses to handle larger orders while maintaining quality and customer satisfaction. Integrating automated systems controls pattern design to fabric transfer, saving time for staff to focus on creativity, and expediting production cycles with data analytics and real-time monitoring. This holistic automation streamlines operations, minimizes waste, and maximizes material usage in Custom DTF Transfers.

Automating your custom DTF (Data Transfer Framework) transfers can significantly boost efficiency and productivity in your business. This comprehensive guide explores the benefits of automation, from improved data accuracy to reduced turnaround times. We delve into practical steps for implementing powerful automation tools and technologies, offering valuable tips to streamline processes and optimize custom DTF transfer workflows. Discover how automation can transform your operations and enhance customer satisfaction.

- Understanding Custom DTF Transfers and Automation Benefits

- Implementing Automation Tools and Technologies for DTF Transfers

- Streamlining Processes: Tips for Effective Custom DTF Transfer Automation

Understanding Custom DTF Transfers and Automation Benefits

Custom DTF (Direct-To-Fabric) Transfers have transformed the way businesses create personalized designs on a variety of materials, particularly lightweight fabrics like t-shirts. This technology allows for precise, high-quality printing directly onto fabric, enabling entrepreneurs to offer unique, custom-designed custom t shirts and products with minimal effort and cost. By automating the process of creating these custom dtf transfers, businesses can significantly streamline their operations.

Automation offers numerous benefits, from increased efficiency and reduced manual labor to improved accuracy and faster turnaround times. Automating dtf printing for light fabrics enables entrepreneurs to handle larger orders without sacrificing quality or speed. This not only enhances customer satisfaction but also opens up opportunities for growth and expansion. By leveraging automation, businesses can focus on strategic aspects of their operation, innovate with new designs, and explore diverse fabric options, ultimately solidifying their position in the market.

Implementing Automation Tools and Technologies for DTF Transfers

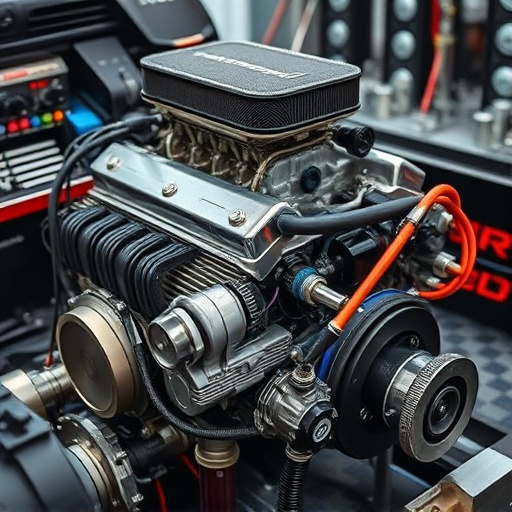

In today’s digital era, businesses aiming to streamline their Custom DTF Transfers operations should seriously consider implementing automation tools and technologies. By integrating automated systems, you can significantly enhance efficiency and productivity in your DTF for Apparel production process. Automation software allows for precise control over each step of the transfer process, from designing and cutting patterns using DTF transfer film to accurately placing these designs onto various fabrics through DTF transfer sheets. This ensures consistency in quality and reduces human error.

Automated solutions also offer time-saving benefits, allowing your team to focus on more complex tasks that demand creativity and strategic thinking. With automated systems handling repetitive tasks like cutting, positioning, and heating, you can expedite the overall production cycle. Moreover, these technologies often incorporate advanced features such as data analytics and real-time monitoring, providing valuable insights into your DTF transfer process for continuous improvement.

Streamlining Processes: Tips for Effective Custom DTF Transfer Automation

In the realm of custom DTF transfers, automation can significantly enhance efficiency and productivity. Streamlining processes is a key aspect of effective automation, allowing businesses to optimize their operations for faster turnaround times and improved customer satisfaction. One powerful strategy involves integrating digital design tools that enable the seamless creation and editing of DTF (Direct-To-Fabric) transfer patterns. By digitizing the design process, businesses can quickly adapt to client requests and ensure consistent, high-quality results.

Additionally, implementing automated cutting machines tailored for DTF prints can revolutionize fabric preparation. These machines precisely cut transfer patterns, minimizing waste and maximizing material utilization. Efficient inventory management systems, coupled with real-time tracking capabilities, further streamline the workflow by ensuring that all necessary materials are readily available. This proactive approach to inventory control prevents delays and allows for a smoother production process, ultimately contributing to the successful automation of custom DTF transfers.

Automating your custom DTF Transfers business is a strategic move that offers numerous advantages, from increased efficiency and reduced errors to faster turnaround times. By implementing the right automation tools and streamlining processes, you can revolutionize how you handle DTF Transfers, ultimately elevating your business’s capabilities in today’s competitive market. Remember that effective automation isn’t just about technology; it’s about optimizing workflows and leveraging digital solutions to focus on what truly matters – providing exceptional custom DTF Transfer services.